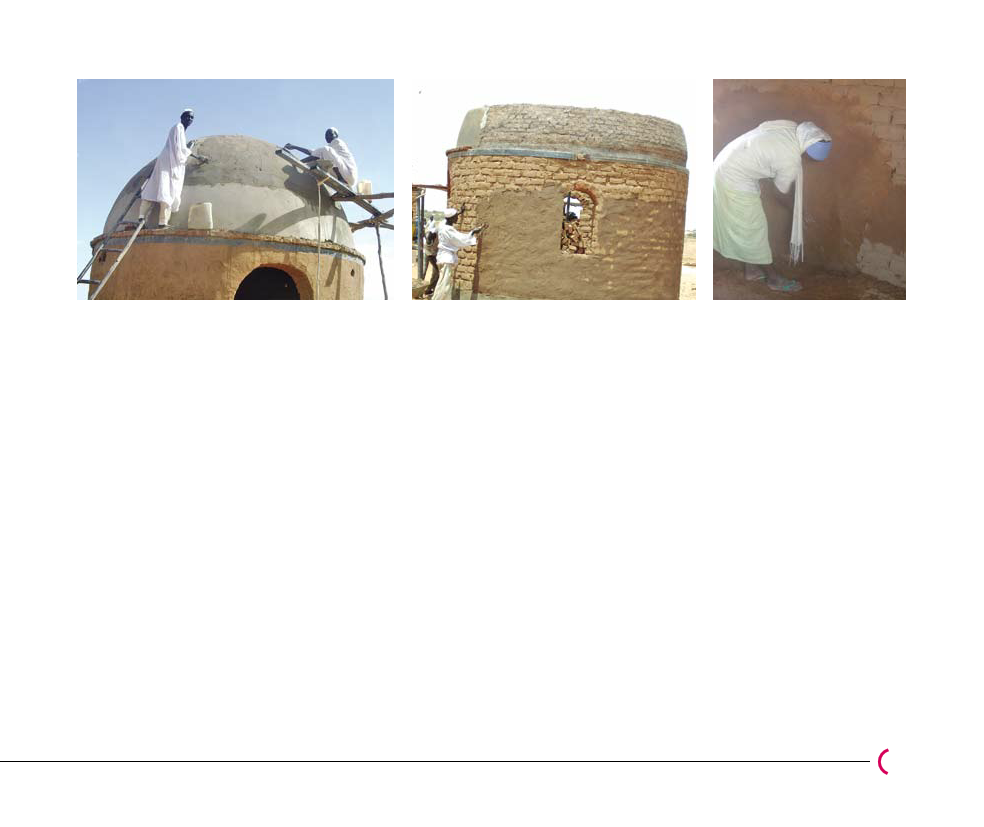

Pic 22. Plastering the roof.

Pic 23. Plastering the outer walls

Pic 24. A lady plasters

the inside walls

4.11. Plastering the roof

This is a very important stage and

can be achieved through a variety

of materials. For example sand can

be used with asphalt and should

be mixed together at a ratio of 1:2

(asphalt / sand). In this case the

asphalt should be heated first and

dried with gasoline or kerosene

before being mixed with soft sand.

It should be applied to the roof in a

layer 2cm thick which will protect

the roof from rain and humidity.

4.12. Plastering the walls on the

outside

The plaster for the outside walls is

made using sand that is mixed with

local materials such as coloured mud mixed with sand or lime.

Local skills and expertise may need to be used at this stage.

This can also be done at an earlier stage as shown in picture

23.

4.13. Plastering the inside walls

Plastering the walls on the inside is made using sand that is

mixed with gum arabic powder. Like the outside walls other

local materials can be used such as coloured mud mixed with

sand or lime (see picture 24).

4.14. The Floor

The floor in most rural homes uses a thin layer of sand and

that is the most appropriate method for this building. If this

house was to be built in an urban area the ground could use

braided brick, stone, concrete or tiles.

Practical Answers Sudan

The Construction of the Timberless House Model

21